Your specialist

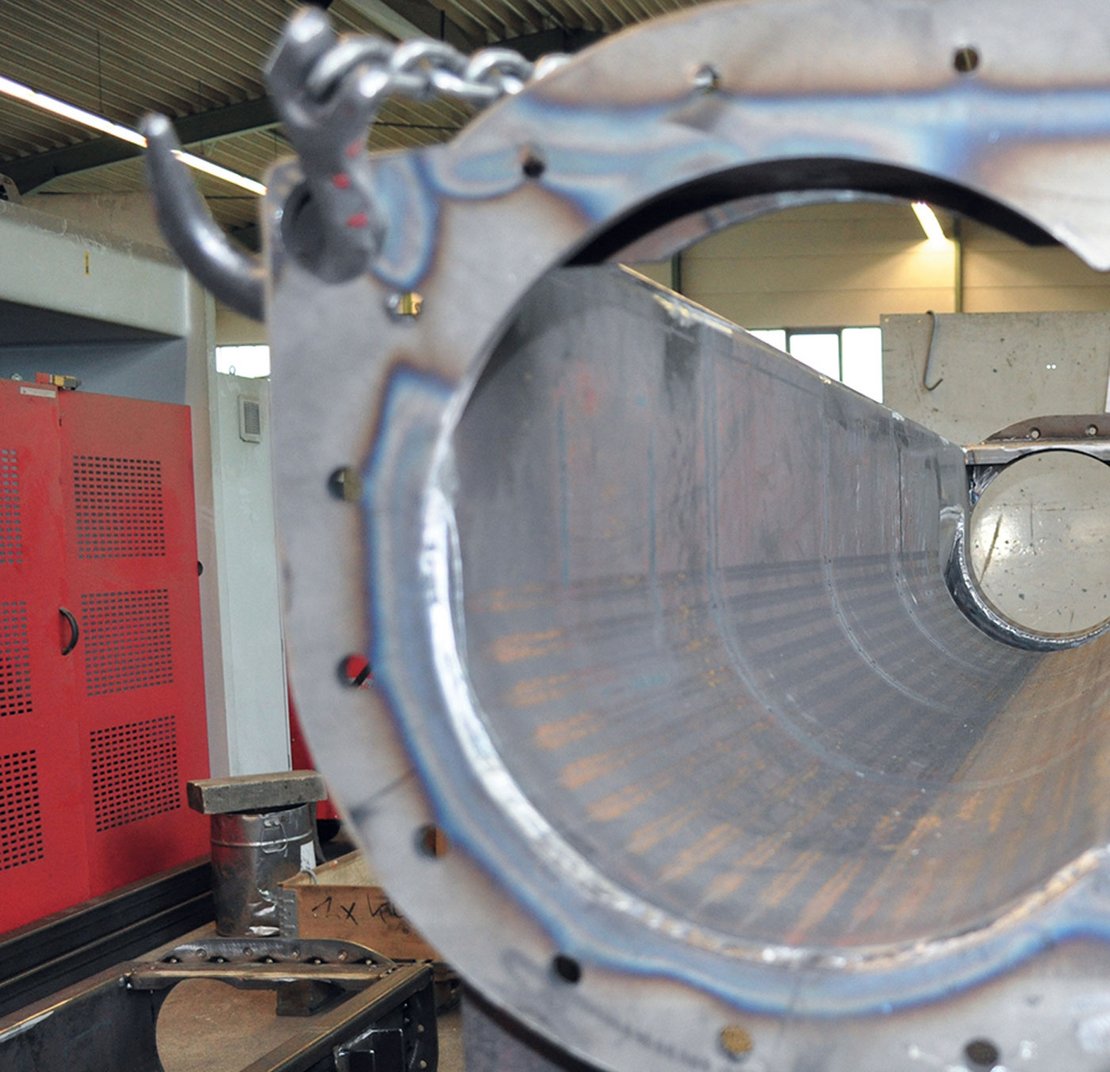

Barl Maschinenbau GmbH in Thierhaupten near Augsburg specialises in the production of components for process technology in the bulk goods area. Our high-quality dosage, conveyor and shut-off devices are gladly accepted by our customers in and outside of the country. In addition to our standard products, we develop problem solutions for difficult poured goods that can only be conveyed, dosed, shut off or loosened up together with our customers. This way, we can offer complete solutions for nearly any systems of poured goods handling.

For more than 200 years, the company has been headquartered in Thierhaupten as a family-owned company. In the area of mechanical process technology for bulk material, the company is able to look back on more than 30 years of experience.

The close cooperation between development, construction and production has enabled us to put technically high- quality products on the market at competitive prices.

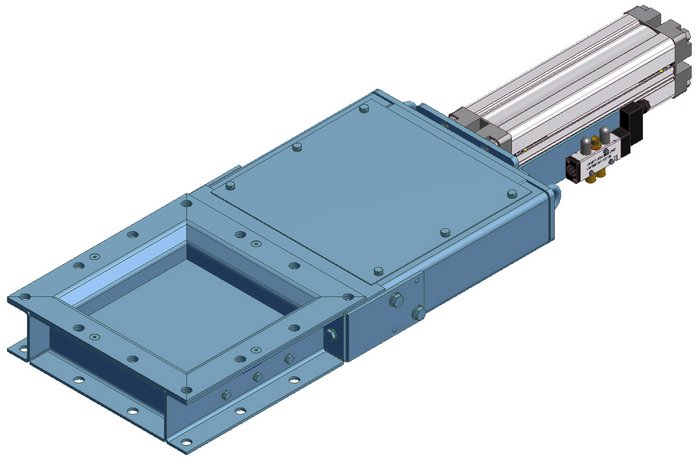

Our Products

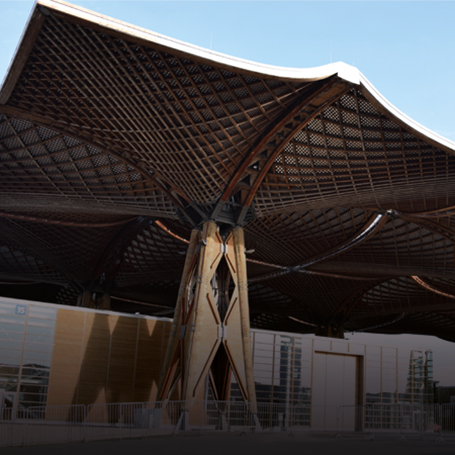

Bulk material technology made in Germany

The individual components and units for the bulk material industry are used for conveying, dosage, loosening, moistening, chopping and shutting off bulk materials: ash, cement, lime, sand, gravel, pharma powder, coffee, sugar, salt, flakes, chips, wood pellets, plastic, Styrofoam, environmentally hazardous dusts and many others.

Our customers work in industrial areas such as environmental technology, power plant technology, the food industry, chemistry, building material industry, petrochemistry, disposal technology, pharmaceutics, and biomass systems.

Job offers - we are looking for you

We are growing continually. Therefore, we are looking for specialists and trainees for our company. If you would like to help our company be successful in a pleasant environment, send your indicative application to:

Barl Maschinenbau GmbH

Frau Gabriele Barl

St.- Vitus- Str. 33

86672 Thierhaupten

Germany

latest

Fast and target-oriented service deployment

Our experienced team, supported by a production depth developed in the long term, coordinates problem solutions in a timely manner. Our continuous target is to be able to produce any workpiece internally in an emergency.

Always available:

We can always be reached via email or phone and are able to react within 24 hours in an emergency.

Our service email is:

info@Barl-mb.de

Our service phone number is:

+049 (0)82765843-0

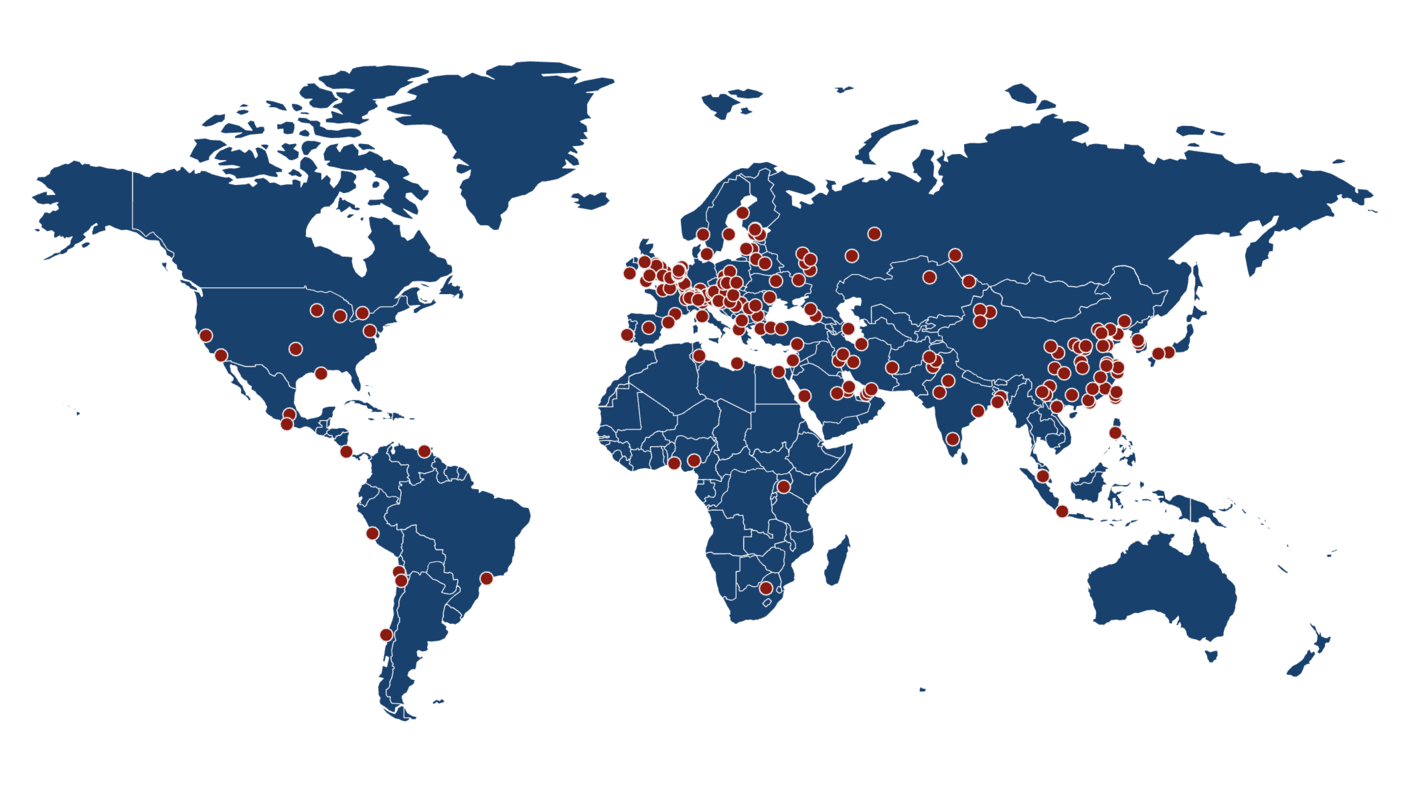

worldwide

Spain, China or the USA - our customers can be found anywhere in the world. They value our quality, safety and the high standard of our products.