Products

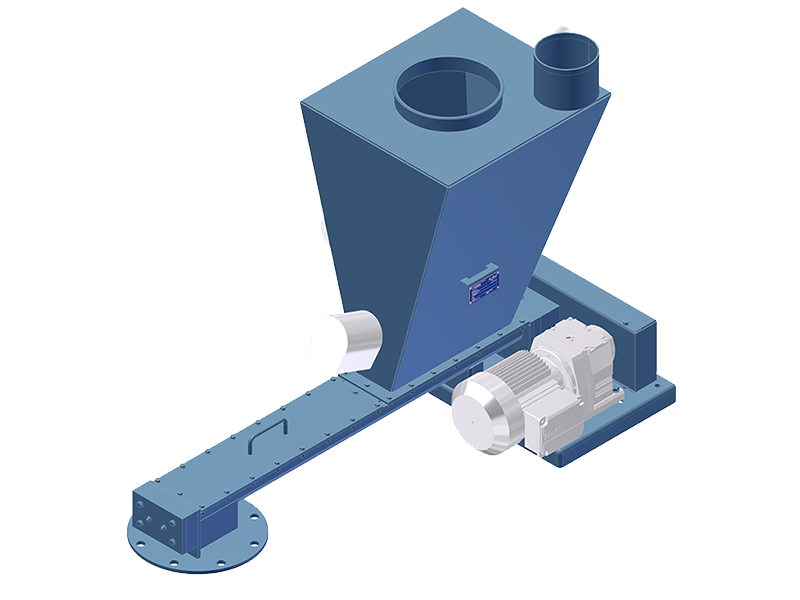

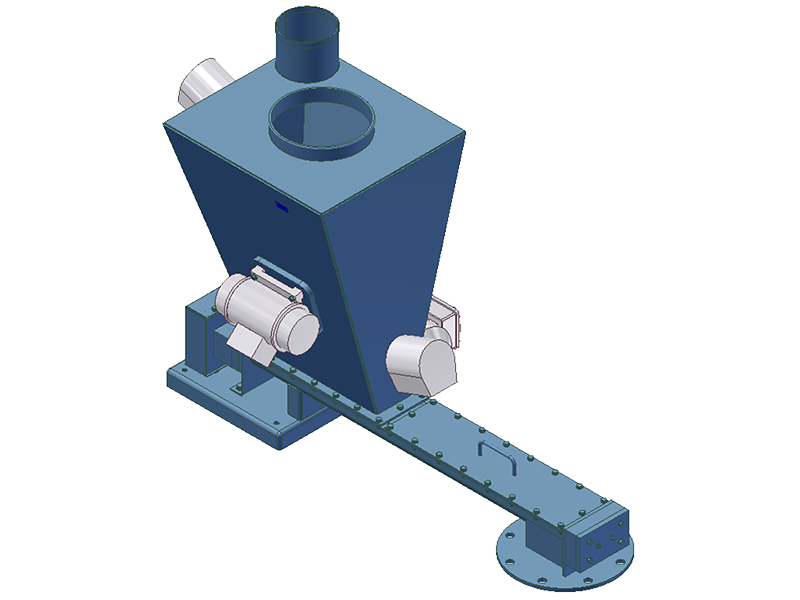

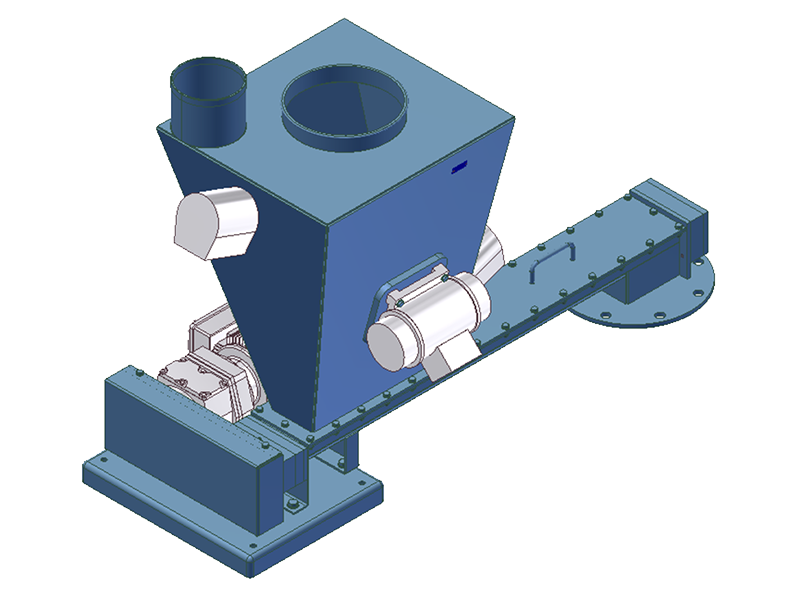

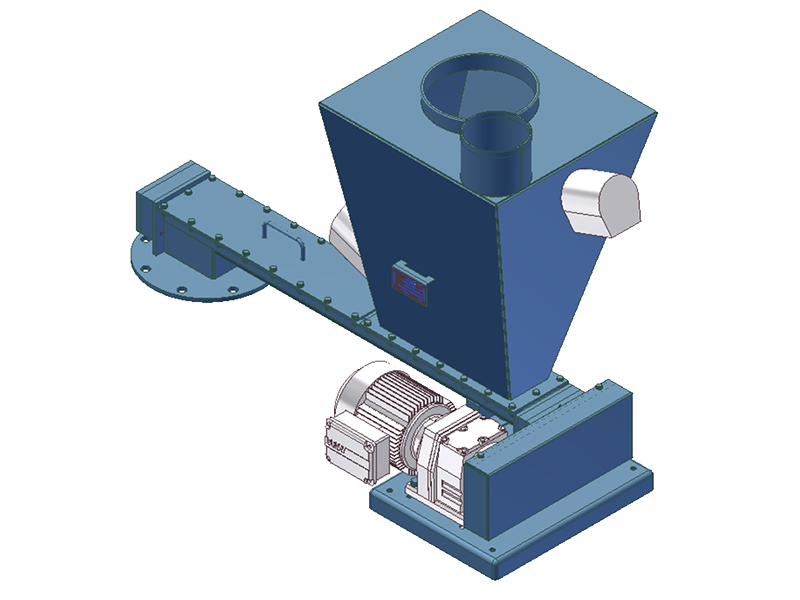

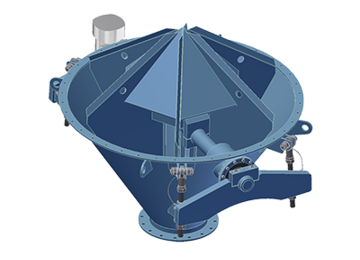

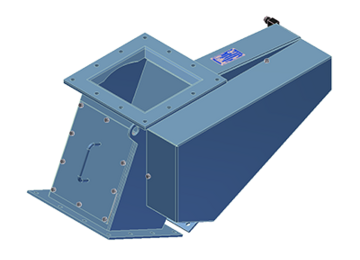

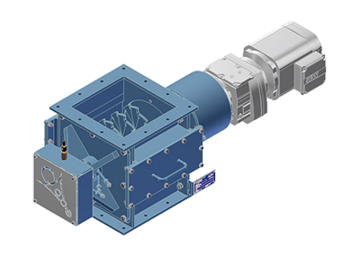

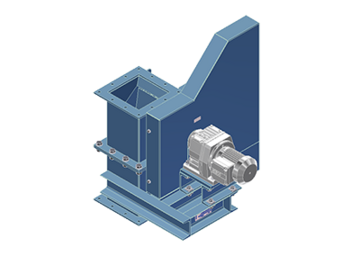

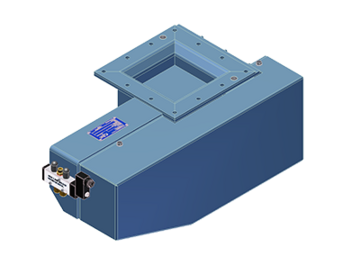

PRECISION METERING DEVICE

BARL precision metering device serve even dosage of smaller dust-shaped and fine-grained bulk materials.

The bulk material must be ready to be conveyed and flowing. With the help of the agitator in the inlet area, a near-constant filling degree can be ensured. Resulting agglomerations in the silo can be chopped and operational safety can thus be increased. The progressive spindle pitch also reduces the danger of bulk material compaction within the conveyor tube. Screw coil and housing are produced to the precise size and thus as tight as possible. The unscrewable conveyor pipe makes disassembly or cleaning of the screw easier.

Outer bearings are part of the serial equipment.

STANDARD SIZES

DN 32 to DN 125

HOUSING MATERIALS

RST-37, S235JRG2, boiler sheet (P265GH), 16Mo3, 1.4301, 1.4541, 1.4571, 1.4828, others on request

SHAFT SEALING

Radial shaft sealing rings or adjustable packing glands

FORCE TRANSMISSION

Direct, with coupling or via chain drive

DRIVE

With fixed or variable speed

TEMPERATURE RANGE

-40° C to +900° C

EX-PROTECTION

ATEX-directive 94/9 EC

PRESSURE SURGE RESISTANT

Up to 10 bar

WEAR PROTECTION

With surface coating, lining or replaceable inserts.

Your contact to us

Would you like to ask us something, have an inquiry or would you like to apply for a job?

Then go ahead, fill out the contact form and send it off. We will definitely get in touch with you.

BARL MASCHINENBAU GMBH

St.-Vitus-Strasse 33

86672 Thierhaupten-Neukirchen

Deutschland

Germany

Phone +049 (0)82765843-0

Fax +049 (0)82765843-50

www.barl-mb.de

info@barl-mb.de