Products

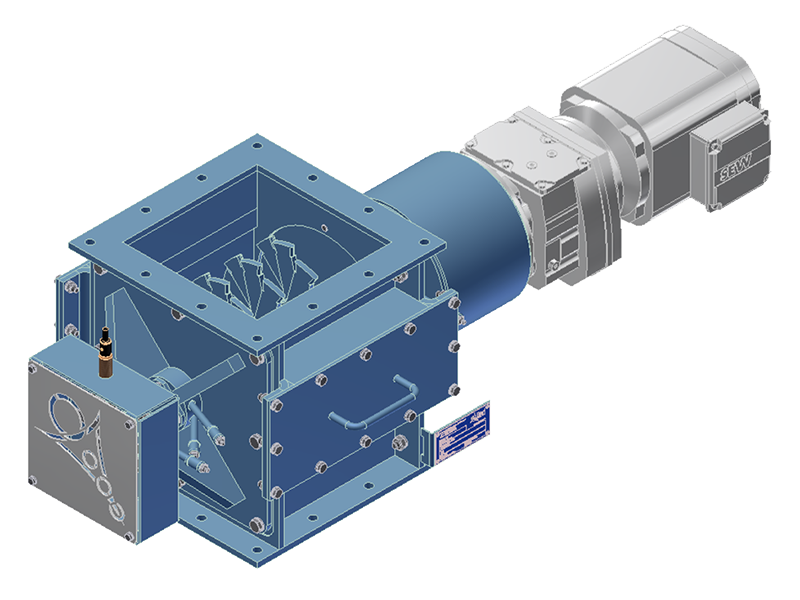

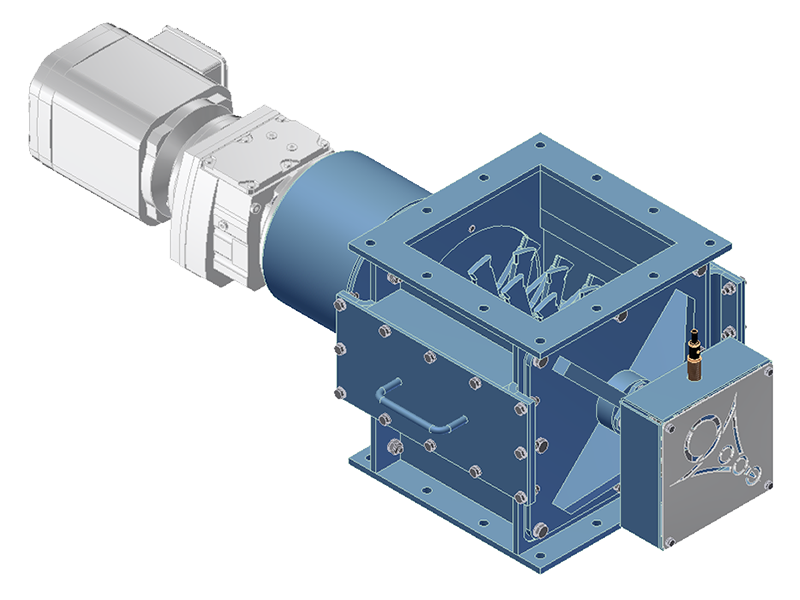

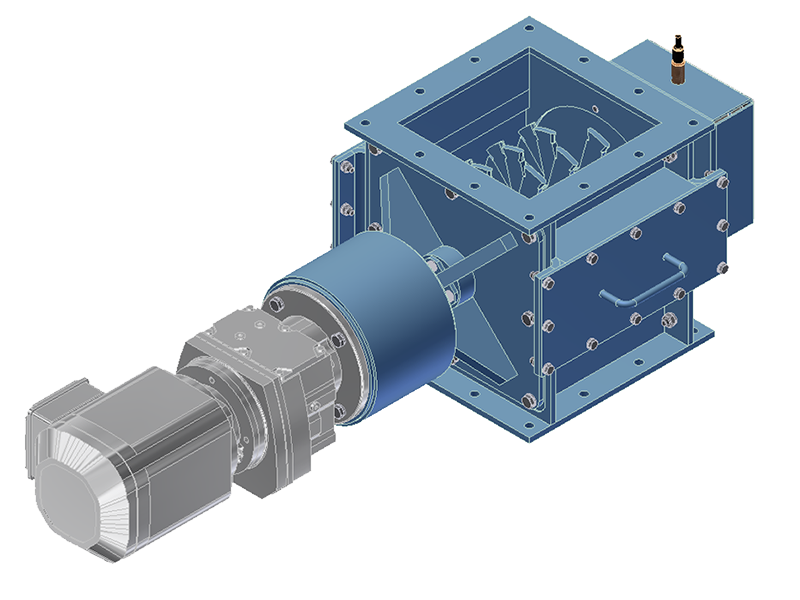

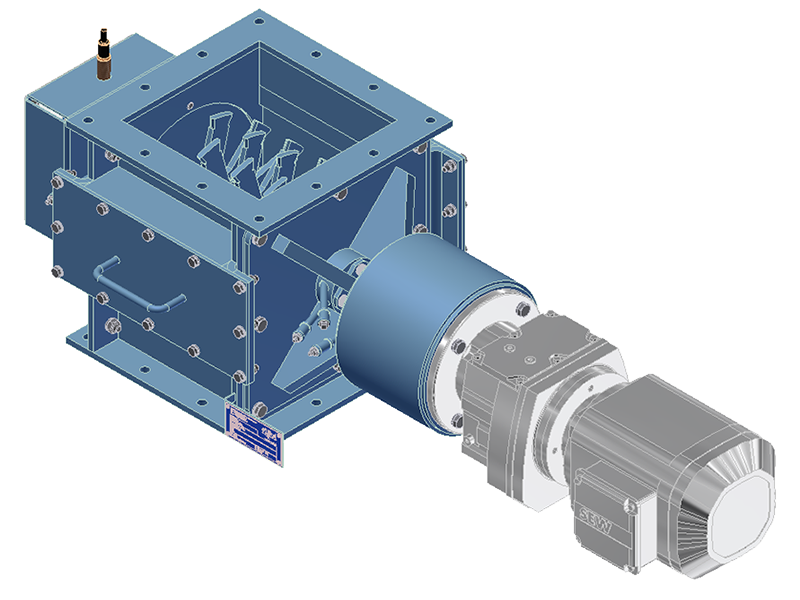

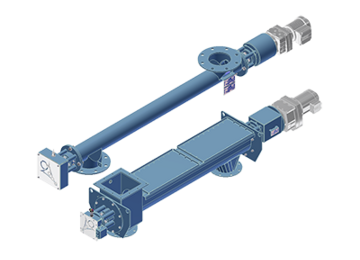

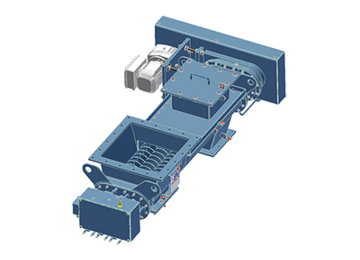

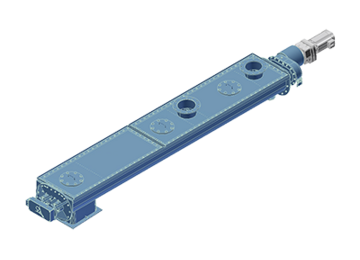

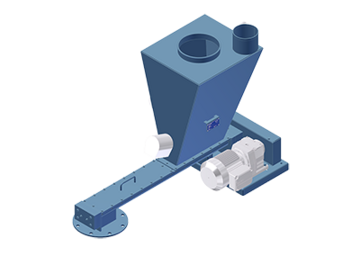

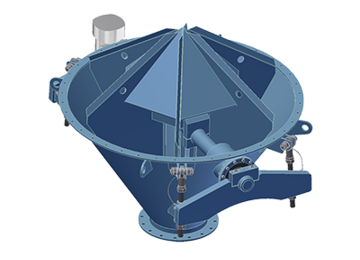

AGGLOMERATE CRUSHER

BARL agglomerate crusher are generally equipped with replaceable beaters. Depending on product properties, we construct them with one, two or more shafts.

Cleaning openings installed by default ensure quick, easy cleaning. The maximum permissible input grain is between 50 and 100 mm, depending on the size of the unit. The end grain is at 10 to 15 mm, depending on equipment and device size.

Our agglomerate crusher are suitable for agglomerates, but not for rock-like products. The bulk material must be supplied to the agglomerate crusher dosed. It cannot have an unlimited supply. Use of a coupling is standard, as is the outer bearing.

STANDARD SIZES

200 x 200 to 1,000 x 1,000, DN 200 to DN 600

HOUSING MATERIALS

S235JRG2, boiler sheet (P265GH), 16Mo3, Hardox 400, 1.4301, 1.4541, 1.4571, 1.4828, others on request

SHAFT SEALING

Radial shaft sealing rings or adjustable packing glands

FORCE TRANSMISSION

Via coupling or chain drive, on request with overload coupling

DRIVE

With fixed or variable speed

TEMPERATURE RANGE

-40° C to +600° C

EX-PROTECTION

ATEX-directive 94/9 EC

PRESSURE SURGE RESISTANT

Up to 10 bar

CIP

Suitable

WEAR PROTECTION

With surface coating, lining or replaceable inserts.

CLEANING

Also available extensible

Your contact to us

Would you like to ask us something, have an inquiry or would you like to apply for a job?

Then go ahead, fill out the contact form and send it off. We will definitely get in touch with you.

BARL MASCHINENBAU GMBH

St.-Vitus-Strasse 33

86672 Thierhaupten-Neukirchen

Deutschland

Germany

Phone +049 (0)82765843-0

Fax +049 (0)82765843-50

www.barl-mb.de

info@barl-mb.de